Graphite Polystyrene

Graphite polystyrene (GPS) has a polymer matrix that contains graphite, a common mineral, a stable, chemically inert form of carbon, composed of many layers of graphene. The inclusion of graphite particles help to increase resistance to heat flow by reflecting radiant heat energy and reduces thermal conductivity to a greater extent than standard polystyrene.

The high-purity graphite particles are introduced into the raw material, polystyrene beads, which are heated at high temperatures and then treated with steam to create the cellularly dense structure in a similar way to standard polystyrene..

In terms of fire, there is some evidence that graphite can improve resistance to the spread of fire, while other studies have also looked at expanded graphite coating on polystyrene bead to improving flame retardancy. The indication is that most graphite polystyrenes are also treated with a fire retardant, although this is unclear and may vary from product to product.

- Certain manufacturers of the product highlight its sustainability credentials including;

- Higher performance, as described above.

- Recyclability, up to 100% with the possibility to contain post-industrial and post-consumer recycled waste.

- Manufacturiung processes are use relatively low-energy steam processes.

- Pentane can be used as a foaming agent, which has a GWP of zero and can be re-used, along with water.

- The product does not contain CFC, HCFC, HFC, formaldehyde, borate or produce methane gas.

In all cases performance characteristics, enviromental aswell as thermal should be cross-checked with individual products, preferrably with third party assessment. For furrher information see article The sustainability of construction works and in particular Environmental Product Declarations and Product Environmental Footprints.

[edit] Related articles on Designing Buildings

- Acrylic.

- Aircrete.

- Celotex RS5000 PIR insulation.

- Composites.

- Grenfell Tower fire.

- Insulation.

- LPCB certification and Kingspan.

- Polyethylene.

- Polyurethane (PUR).

- Persistent organic pollutants (POP)

- Phenolic foam insulation.

- Polyurethane spray foam in structurally insulated panels and composite structures.

- SABRE.

- Transparent insulation materials.

- Types of insulation.

- Types of plastic in construction.

- Types of rigid foam insulation.

Featured articles and news

Art of Building CIOB photographic competition public vote

The last week to vote for a winner until 10 January 2025.

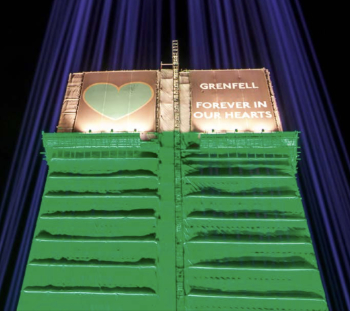

The future of the Grenfell Tower site

Principles, promises, recommendations and a decision expected in February 2025.

20 years of the Chartered Environmentalist

If not now, when?

Journeys in Industrious England

Thomas Baskerville’s expeditions in the 1600s.

Top 25 Building Safety Wiki articles of 2024

Take a look what most people have been reading about.

Life and death at Highgate Cemetery

Balancing burials and tourism.

The 25 most read articles on DB for 2024

Design portion to procurement route and all between.

The act of preservation may sometimes be futile.

Twas the site before Christmas...

A rhyme for the industry and a thankyou to our supporters.

Plumbing and heating systems in schools

New apprentice pay rates coming into effect in the new year

Addressing the impact of recent national minimum wage changes.

EBSSA support for the new industry competence structure

The Engineering and Building Services Skills Authority, in working group 2.

Notes from BSRIA Sustainable Futures briefing

From carbon down to the all important customer: Redefining Retrofit for Net Zero Living.

Principal Designer: A New Opportunity for Architects

ACA launches a Principal Designer Register for architects.